Putting Community Safety Ahead ⭐⭐⭐⭐⭐

Passive Fire Protection

Fire Contained. Safety Secured.

The principle of "Precaution is better than Cure" underscores the importance of pro-active safety measures. This proposal highlights the numerous benefits of implementing Passive fire protection systems as a key component of fire safety protocols, demonstrating how it better than traditional methods such as fire extinguishers and sprinklers in various critical aspects.

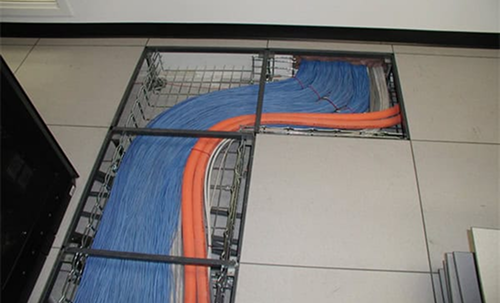

Majority fire-break outs are initiated due to electrical short-circuits and overloads which can be restricted.

Advantages of Fire-Resistant Cable Coating / Fire Barriers / Sealing Systems

Areas of Application for our “Passive fire Protection System

A. Wall & floor openings: Openings in the separating walls or floors shall be fitted with 4 hour fire resistance barrier systems (Mortar barrier systems for load bearing applications or Mineral wool board barriers for light weight & easy retrofitting option). It will be suitable for cables passing through cable shafts, cables running through wall penetrations, below electrical panels.

B. Fire Passivation of electrical cables: The intumescent cable coating shall be applied at critical areas to the required thickness for a 4 hour fire rating. Horizontal cables to be intermittently coated at every 3-4 meters and vertical cables to be coated completely depending on the layout. Cable connections to all equipment with high electrical load to be covered

C. Electrical conduits / Ducts: These are to be sealed by in-situ application of fire grade sealants with 2 hour rating.

D. Transformer / Substations/ Conduits/ Cable Shafts/ Electrical panel area to be protected.

Awareness and Accessibility of Fire Extinguishers

Our Certifications

We gladly inform that we are the only company which is approved by Centre for Fire, Explosives & Environment Safety (CFEES, DRDO) & having various certifications / Test reports by many government approved labs as mentioned below.

| Sr. No. | Test | Standard | Organization | Results |

|---|---|---|---|---|

| A | Non-Combustibility Test | BS476: Part IV | CFEES, DRDO | Approved |

| B | Fire propagation prevention on cable surface for a minimum period of 120 minutes at 0.8mm DFT. | IEC 60332-3-21 | CBRI, Roorkee | Approved |

| C | Fire propagation prevention on cable surface for a minimum period of 240 minutes at 1.6mm DFT. | IEC 60332-3-21 | CBRI, Roorkee | Approved |

| D | Cable fire protection /fire survivability - circuit integrity for a minimum period of 50 minutes | IEC 60331-11 | CBRI, Roorkee | Approved |

| E | Grouped cables fire suppression, ampacity, weathering, etc. | FM 3971 | FM, USA | Approved |

| F | Hydrocarbon Fire test temperature (>1100° C) | CBRI, Roorkee | Approved | |

| G | Flame Retardant Test | IEEE 383 | CBRI, Roorkee | Approved |

| H | Toxicity Index | NES-713 NCD-1409 |

CBRI, Roorkee | Approved |

| I | 14 Days water immersion test | IICT-CSIR, Hydrabad | Approved | |

| J | Heat dissipation | ERDA, Vadodara | Approved | |

| K | Smoke Density • 99% (max. light transmittance) • 1.0 (Smoke density rating) |

ASTM D 2843 | NABL Accredited Lab | Approved |

| J | Oxygen index test | ASTM D 2863-2000 | ERDA, Vadodara | Approved |

| L | Oxygen index test | ASTM D 2863-2000 | ERDA, Vadodara | Approved |

| M | Bending Test of cable coating via loop test method • At Room Temperature • At high temperature 60° C • At low temperature -04° C |

ERDA, Vadodara | Approved | |

| M | Halogen acid gas (<35 %) | IEC 60754 pt-1 | NABL Accredited Lab | Approved |